Shore power converters have built in isolation transformers that protect yachts from galvanic corrosion, and reverse polarity, in addition to providing complete electrical isolation of shore power from yacht’s electrical system. Two primary types of transformers are widely used: traditional low-frequency (LF) transformers and high-frequency (HF) transformers. Understanding the differences between these technologies and their impact on power systems can help make informed decisions when selecting the best converter system for your yacht.

Traditional (Low-Frequency) Transformers

Traditional transformers, also known as low-frequency or iron-core transformers, operate at the line frequency of the power source, typically 50 or 60 Hz. They have a primary and secondary winding wrapped around the core, insulated from each other. They provide electrical isolation, protecting the yacht’s electrical system from faults and noise from the shore power supply. These transformers are known for their robust construction, using iron or steel cores and thicker copper windings. This design allows them to withstand mechanical stresses, heat, and electrical noise, making them highly durable and reliable.

These transformers excel in marine applications where long-term reliability and resilience is important. Their ability to manage heat effectively and tolerate short-term overloads without damage makes them a preferred choice in demanding environments. Furthermore, their resistance to electrical noise ensures consistent performance, even in electrically noisy settings.

HF (High-Frequency) Transformers

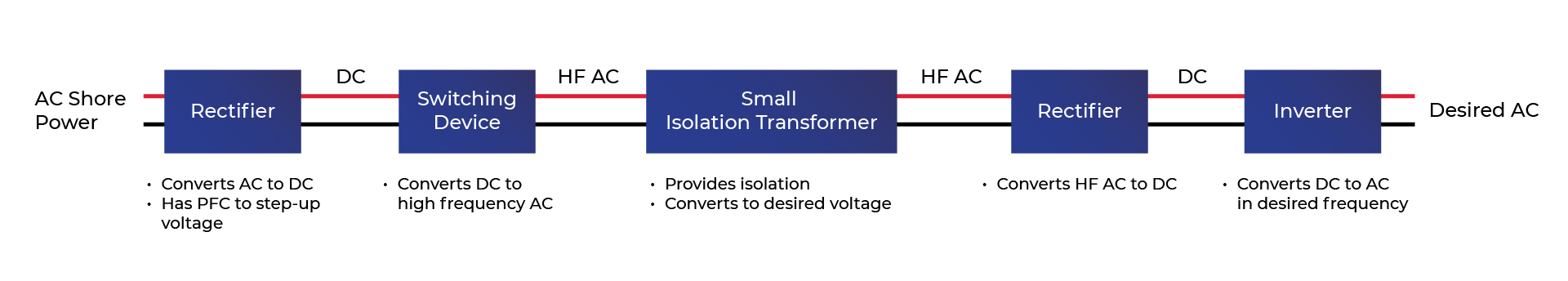

High-frequency transformers, on the other hand, operate at much higher frequencies (often in the kHz range), allowing them to be smaller and lighter than their traditional counterparts. These transformers rectify incoming AC power to DC, then use a high-frequency DC-DC converter with switching devices. This rapidly turns the DC power on and off, creating high-frequency AC. This high-frequency AC is then passed through a smaller, high-frequency isolation transformer, which utilizes ferrite cores and fine gauge wire to minimize losses. The result is a compact, lightweight transformer that provides complete isolation from shore power.

High Frequency System for Converters

While the compact design of high-frequency transformers offers significant advantages in terms of size and weight, it comes with certain trade-offs. The HF system prioritizes compactness and efficiency but may be less effective at suppressing high transient voltages. Switching devices which require complex control and can introduce noise or be more susceptible to failure, which can be a concern in marine applications.

Our Converter System vs. High-Frequency Systems

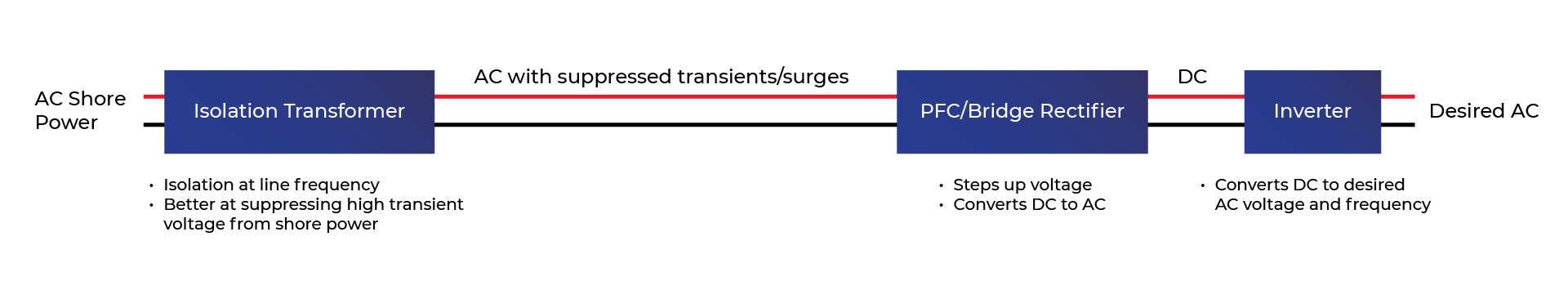

When it comes to power conversion, the choice of system architecture can have a significant impact on performance, reliability, and safety. In the diagram below, shows our traditional transformer-based system for shore power converters.

ASEA’s Converter System

ASEA’s converter system employs a traditional isolation transformer that operates at line frequency. This setup offers better protection against high transient voltages, such as those caused by lightning strikes or fluctuations in shore power. In contrast, the high-frequency system’s smaller isolation transformer may not provide the same level of protection, potentially exposing your equipment to damage. The robust nature of the line-frequency isolation transformer ensures that your system remains insulated from sudden surges, providing an extra layer of security. This is particularly crucial in marine environments where power stability can be unpredictable.

With Power Factor Correction (PFC) integrated with a bridge rectifier, our system ensures efficient power conversion with minimal harmonic distortion. This results in better overall power quality, which is essential for sensitive equipment. High-frequency systems, while compact, may introduce noise and require complex control mechanisms that can compromise power quality.

Traditional transformer-based systems are more resilient to environmental factors like moisture, dust, and temperature extremes. This makes it ideal for marine applications where long-term reliability is crucial. High-frequency systems, although efficient, may be more susceptible to environmental stresses due to their complex design and reliance on smaller components thereby having a shorter lifespan.