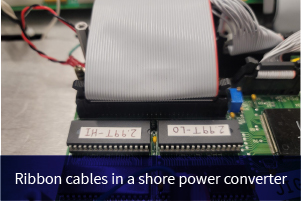

In a marine electrical system, shore power converters are essential for providing reliable power to yachts and vessels. One often overlooked yet vital component of these systems is the ribbon cable. These flat, flexible cables play a crucial role in maintaining connections between various internal components of the shore power converter. However, improper handling and lack of maintenance can lead to system failures, costly downtime, and electrical hazards.

In this guide, we’ll dive into essential maintenance tips for ribbon cables, focusing on best practices that every service technician should know to ensure the optimal performance of shore power converters.

Inspect the Environment Before Disconnecting Ribbon Cables

Before you even think about disconnecting a ribbon cable in a shore power converter, it’s important to evaluate the surrounding environment for potential hazards like dust and dirt. Gabriel Vargas, Head of Product Engineering at ASEA Power Systems, stresses the importance of maintaining a clean environment to prevent contaminants from entering open connectors.

Best Practices:

- Visual inspection: Check for any dirt, dust, or debris around the connection area. These contaminants can easily fall into exposed connectors when the cable is disconnected.

- Use a vacuum to clean the area thoroughly before disconnecting. Avoid using compressed air, which can blow debris into sensitive connectors, worsening the problem.

- Create a clean workspace around the connection point to ensure that no contaminants can enter during maintenance.

Handle Ribbon Cables with Care During Disconnection

Ribbon cables are delicate, and mishandling can easily lead to damage. Pulling directly on the cable instead of the connector can break internal wires, leading to poor connectivity and intermittent system faults.

Disconnection Guidelines:

- Grip the connector, not the cable: Always disconnect ribbon cables by pulling gently on the connector, not the cable itself. This minimizes the risk of internal wire breakage.

- Pull evenly from both sides of the connector to prevent misalignment or damage to the pins.

- Avoid force: If the connector resists, ensure that no fasteners or clips are holding it in place before applying more pressure.

Clean Connection Points After Disconnection

Once the ribbon cable is disconnected, it’s critical to ensure that no debris or dirt enters the exposed connectors. Unclean connectors can lead to poor contact, resulting in system inefficiencies or complete failures in the shore power converter.

Cleaning Tips:

- Vacuum around the connector to remove any loose debris. If compressed air must be used, ensure all connectors are covered and sealed.

- Inspect for corrosion or damage: Look for any signs of wear, such as rust or bent pins. If corrosion is present, clean the contacts gently using an appropriate solution and soft brush.

- Ensure that the connection area is free of contaminants before reinstalling or reconnecting any ribbon cable.

Prevent Stress and Strain on Ribbon Cables During Reinstallation

Reinstalling ribbon cables in a shore power converter can introduce unnecessary stress, especially in tight compartments. Excessive strain on the cable can reduce its lifespan and compromise the reliability of the system.

Reinstallation Guidelines:

- Avoid sharp bends or twists in the cable. Sharp angles can weaken the cable over time and lead to electrical failure.

- Use strain relief mechanisms if available. This will prevent the cable from being stretched or stressed during operation, reducing wear and tear.

- Align connectors properly and ensure the pins fit snugly into the sockets. Misaligned connectors can cause signal loss and equipment malfunctions.

Troubleshoot Ribbon Cable Issues in Shore Power Converters

If the shore power converter experiences any faults, ribbon cables should be one of the first components checked during the diagnostic process. These cables are prone to wear, especially in high-heat or high-vibration environments typical in marine settings.

Troubleshooting Steps:

- Check for visible damage: Inspect the cable for any signs of wear, such as cracks, pinching, or fraying. Damaged cables can cause intermittent power loss or communication errors.

- Test connectivity: Use a multimeter to check for continuity in the cable. This will help identify any breaks or internal issues.

- Ribbon Cable Testers: For more detailed troubleshooting, ribbon cable testers available on the market can verify the integrity of all connections, making it easier to detect faults across multiple lines in a single test.

- Check for loose connections: Ensure that all ribbon cables are fully seated in their connectors. Even a small misalignment can lead to significant operational issues.

Ribbon cables in shore power converters may seem like a minor component, but their proper maintenance is critical to ensuring the reliable operation of the entire system. By following these essential tips—cleaning the environment, handling cables carefully, inspecting for damage, and utilizing ribbon cable testers—service technicians can prevent common issues and extend the lifespan of both the ribbon cables and the shore power converters they support.

Taking the time to properly maintain ribbon cables will result in fewer system failures, reduced downtime, and more reliable power delivery for marine vessels. Remember: attention to detail can make all the difference when it comes to maintaining the high standards of ASEA Power Systems’ shore power converters.